250LPH Electrophoretic Paint Recycling Equipment

250LPH-

Structural features

1) The electrophoretic paint special roll ultrafiltration membrane adopts large flow cross-flow filtration to filter out the large molecular paint in the water, achieving the effect of concentration and purification.

2) The modified diamond grid can effectively improve the water flow distribution of the inlet water, reduce the pressure loss by 20%, and reduce the number of cleaning and flushing by 35%.

3) The surface of the special membrane is smooth, without a "peak-valley" structure, the roughness is less than 5nm, and it has good anti-pollution performance, higher concentration multiples, and stronger anti-fouling and blocking performance.

4) The contact angle test of the membrane surface is less than 45 degrees, with good hydrophilicity and low isoelectric point. The energy consumption is reduced by 20% and the average life is extended by 1.5 times.

The main interception principle of the electrophoretic paint membrane is to intercept the large molecular substances in the wastewater by the pore size. The pore size of the Yixuan electrophoretic paint membrane is about 1nm. According to the particle size analysis report of the electrophoretic paint cleaning water solution, it can be seen that the electrophoretic paint special concentration membrane can 100% intercept the electrophoretic paint in the electrophoretic paint clear water.

-

Process principle and process description

1) Process principle

Electrophoretic paint ultrafiltration membrane is a membrane element that is specialized in filtering electrophoretic paint. It is mainly used in automobile manufacturing, petrochemical and other industries. Many companies have specially developed electrophoretic paint ultrafiltration membranes, such as Suez, Lisheng, etc.

Electrophoretic paint membrane concentration principle: The water treatment principle of electrophoretic paint ultrafiltration membrane is a membrane element that uses pressure difference as the driving force. Applying appropriate pressure on one side of the electrophoretic paint ultrafiltration membrane can screen out solute molecules smaller than the pore size, and can separate particulate impurities with a molecular weight greater than 500 Daltons and a particle size greater than 2-20 nanometers. At present, our electrophoretic paint ultrafiltration membrane has developed to the third generation. The third generation is improved and innovated on the basis of the original technology. The filter membrane is 0.1μm thick and has stronger high temperature resistance. The electrophoretic paint ultrafiltration membrane is a porous gel attached to a 100-1000um thick porous support plate.

Electrophoretic paint ultrafiltration membrane is mainly composed of polymer materials such as cellulose acetate, cellulose acetate ester, polyethylene, polysulfone and polyamide. When designing the electrophoretic paint ultrafiltration membrane, the pore size specifications are consistent, and the rated pore size range is between 0.001-0.02 microns.

The structural principle of ultrafiltration of electrophoretic paint ultrafiltration membrane: It is usually composed of a very thin and dense cortex on the surface and a porous support layer under the cortex. The dense cortex is a functional layer that plays a role in filtering and intercepting pollutants. The structure of the electrophoretic paint ultrafiltration membrane is divided into symmetrical structure and asymmetrical structure. The symmetrical structure has no cortex, and the directions of water inflow and water production in all pores are consistent, which belongs to deep filtration, the asymmetrical structure has this dense surface layer and a bottom layer dominated by finger-like structure. The surface layer thickness is generally less than 0.1μm, and has orderly arranged micropores. The thickness of the bottom layer is generally 200-250μm, which belongs to surface filtration.

Membrane chemical composition: special patented polysulfone semipermeable membrane (ps)

Membrane model: molecular weight cut-off about 10000Mwco

Membrane structure: ultrafiltration membrane for roll electrophoretic paint

Application: special design,

Optional: water inlet channel 28mil, 31mil, 34mil.

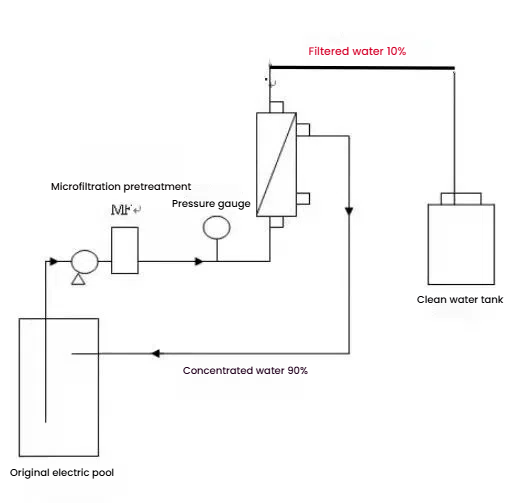

Membrane diameter: 43 inches, 8 inches Principle of use of electrophoretic paint ultrafiltration membrane:OperationWhen the electrophoretic paint ultrafiltration membrane is operated for the first time, the corresponding valves should be opened to ensure that the membrane channel is unobstructed. After turning on the feed pump, the circulation pump is turned on by frequency conversion. Ensure that the inlet pressure value is between 0.1-0.5MPa. If it exceeds 0.5MPa, the electrophoretic paint ultrafiltration membrane will automatically shut down. If the electrophoretic paint membrane assembly uses resin as the shell material, then these membrane assemblies cannot be exposed to direct sunlight to avoid aging of the membrane assembly.Operation parameters:Maximum inlet pressure: 75psiNormal pressure drop: 20psiMaximum pressure drop: 30psiMaximum continuous operating temperature: 60℃Normal operating temperature range: 10-55℃Disinfection cycle temperature: 95℃Maximum pH range: 1.5-13Maximum allowable residual chlorine (cleaning): 200ppmpHH value: 10-10.5ShutdownIf the electrophoretic paint ultrafiltration membrane needs to be shut down, the circulation pump, feed pump, and valve should be turned off in sequence by frequency conversion. When shutting down, it is also necessary to ensure that the electrophoretic paint ultrafiltration membrane is filled with water to prevent the membrane assembly from dehydrating.FlushingThis flushing process is only for the membrane assembly and does not include the circulation pipeline. Open the corresponding valve during flushing and turn on the cleaning pump. Pay attention to the changes in the water tank level during cleaning and replenish water in time. Flushing stop: turn off the feed pump and close all valves. During flushing, ensure that the water pressure and water volume inside the membrane assembly are at normal water levels.2) Schematic diagram of the electrophoretic paint process

Principle of use of electrophoretic paint ultrafiltration membrane:OperationWhen the electrophoretic paint ultrafiltration membrane is operated for the first time, the corresponding valves should be opened to ensure that the membrane channel is unobstructed. After turning on the feed pump, the circulation pump is turned on by frequency conversion. Ensure that the inlet pressure value is between 0.1-0.5MPa. If it exceeds 0.5MPa, the electrophoretic paint ultrafiltration membrane will automatically shut down. If the electrophoretic paint membrane assembly uses resin as the shell material, then these membrane assemblies cannot be exposed to direct sunlight to avoid aging of the membrane assembly.Operation parameters:Maximum inlet pressure: 75psiNormal pressure drop: 20psiMaximum pressure drop: 30psiMaximum continuous operating temperature: 60℃Normal operating temperature range: 10-55℃Disinfection cycle temperature: 95℃Maximum pH range: 1.5-13Maximum allowable residual chlorine (cleaning): 200ppmpHH value: 10-10.5ShutdownIf the electrophoretic paint ultrafiltration membrane needs to be shut down, the circulation pump, feed pump, and valve should be turned off in sequence by frequency conversion. When shutting down, it is also necessary to ensure that the electrophoretic paint ultrafiltration membrane is filled with water to prevent the membrane assembly from dehydrating.FlushingThis flushing process is only for the membrane assembly and does not include the circulation pipeline. Open the corresponding valve during flushing and turn on the cleaning pump. Pay attention to the changes in the water tank level during cleaning and replenish water in time. Flushing stop: turn off the feed pump and close all valves. During flushing, ensure that the water pressure and water volume inside the membrane assembly are at normal water levels.2) Schematic diagram of the electrophoretic paint process 3) Process descriptionStep 1: The daily volume of electrophoretic paint wastewater discharged from the electrophoretic paint pure water cleaning tank 22 is about 40m3, which enters the collection tank 1. The water quality pH value of the discharged water is about 6, the suspended solids are about 50mg/L, and the conductivity is about 50-60.Step 2: The wastewater from the collection tank 1 enters the transfer tank 2. The wastewater in the transfer tank is pumped into the first-level special electrophoretic paint concentration membrane through the circulation pump, and concentrated by cross-flow filtration. The cross-flow ratio of cross-flow filtration is 15:1. The first-level concentrated fresh water enters the fresh water tank 4, and the concentrated liquid after the first-level concentration enters the second-level concentration system. The second-level concentrated fresh water enters the transfer tank 2. The concentrated liquid of the second-level concentration is filtered and regularly added to the electrophoretic paint tank for reuse, the two-stage concentration system uses the electrophoretic paint special membrane produced by us, and the membrane model is YX-EPUF-8040.Step 3: The fresh water in the fresh water barrel 4 after being concentrated by the first-class special electrophoretic paint concentration membrane enters the RO system, the fresh water of the RO system enters the RO fresh water barrel 7, and the concentrated water of the RO system enters the sewage treatment station built by the factory for treatment and discharge after reaching the standard.Step 4: The fresh water in the RO fresh water barrel 7 enters the activated carbon + cation and anion exchange system 9 through the lifting pump 8 and enters the pure water barrel 10 after filtration. The pure water barrel of the pure water barrel is pumped into the workshop cleaning tank 24 for reuse through the variable frequency pump 11.Step 5: When the electrophoretic paint concentration membrane has been running for about 3 months, it is soaked in 3‰ acetone solvent on Saturday or Sunday for 24 hours, and the acetone is collected again in a 30L special barrel for storage and reused for the next soaking.Step 6: After soaking, the electrophoretic paint concentration special membrane is rinsed with clean water and put into use.4) Electrophoretic paint process control standards after reuse

3) Process descriptionStep 1: The daily volume of electrophoretic paint wastewater discharged from the electrophoretic paint pure water cleaning tank 22 is about 40m3, which enters the collection tank 1. The water quality pH value of the discharged water is about 6, the suspended solids are about 50mg/L, and the conductivity is about 50-60.Step 2: The wastewater from the collection tank 1 enters the transfer tank 2. The wastewater in the transfer tank is pumped into the first-level special electrophoretic paint concentration membrane through the circulation pump, and concentrated by cross-flow filtration. The cross-flow ratio of cross-flow filtration is 15:1. The first-level concentrated fresh water enters the fresh water tank 4, and the concentrated liquid after the first-level concentration enters the second-level concentration system. The second-level concentrated fresh water enters the transfer tank 2. The concentrated liquid of the second-level concentration is filtered and regularly added to the electrophoretic paint tank for reuse, the two-stage concentration system uses the electrophoretic paint special membrane produced by us, and the membrane model is YX-EPUF-8040.Step 3: The fresh water in the fresh water barrel 4 after being concentrated by the first-class special electrophoretic paint concentration membrane enters the RO system, the fresh water of the RO system enters the RO fresh water barrel 7, and the concentrated water of the RO system enters the sewage treatment station built by the factory for treatment and discharge after reaching the standard.Step 4: The fresh water in the RO fresh water barrel 7 enters the activated carbon + cation and anion exchange system 9 through the lifting pump 8 and enters the pure water barrel 10 after filtration. The pure water barrel of the pure water barrel is pumped into the workshop cleaning tank 24 for reuse through the variable frequency pump 11.Step 5: When the electrophoretic paint concentration membrane has been running for about 3 months, it is soaked in 3‰ acetone solvent on Saturday or Sunday for 24 hours, and the acetone is collected again in a 30L special barrel for storage and reused for the next soaking.Step 6: After soaking, the electrophoretic paint concentration special membrane is rinsed with clean water and put into use.4) Electrophoretic paint process control standards after reuseProcess

Control indicators

Control parameters

Remark

Cleaning tank 24 water inlet requirements

1. Conductivity

2. Suspended matter

3. Metal ions

4. Water requirementsResistivity ≥ 2 megohms

≤ 0.5mg/L

Cannot be detected

The conductivity of the dilution tank 24 should not exceed 50us/cm\

Cleaning tank 22 water quality

1. Conductivity

2. Suspended matter

3. Metal ionsConductivity ≤50us/cm

≤100mg/LTransparent swimming tank 21 requirements

1. Conductivity

2. pH

3. Filtration system600~800μs/cm

4.5~5.0

1um filter continuously filtersSpecial electrophoresis concentration membrane system

1. Conductivity requirements

2. Suspended matter requirements

3. Metal ions

4. Water intake

5. Water output≤50us/cm

≤100mg/L

No requirement

40m3/d

39.85m3/dRO system

1. Conductivity requirements

2. Suspended matter requirements

3. Metal ions

4. Water intake

5. Water output≤50us/cm

≤5mg/L

No requirement

39.85m3/d

33.87m3/dCation and Anion Exchange System

1. Conductivity requirements

2. Suspended matter requirements

3. Metal ions

4. Water intake

5. Water output≤10us/cm

≤1mg/L

≤1mg/L

33.87m3/d

33.87m3/dProcess design parameters:(I) Design parameters for primary concentration(1) Pump flow rate: Q=48m3/h(2) Pump head: H=26m(3) Pump model: MPH-667 5.5KW(4) Microfiltration filter: 40-inch 16-core stainless steel filter, filtration accuracy 5μ.(5) Ratio of concentrated liquid and permeate in the membrane assembly: 15:1(6) Special membrane for electrophoretic paint: Roll membrane model: EDUP-8040.(II) Design parameters for secondary concentration(1) Pump flow rate: Q=30m3/h(2) Pump head: H=26m(3) Pump model: MPH-665 4KW(4) Microfiltration filter: 40-inch 16-core stainless steel filter, filtration accuracy 5μ.(5) Ratio of concentrated liquid and permeate of membrane assembly: 15:1(6) Special membrane for electrophoretic paint: roll membrane model: EDUP-8040.